Techflex® Flexo® Tinned Copper Braided Cable Sleeving

EMI, RFI, & ESD Shielding, Grounding & Protection Sleeving

0.0 / 5

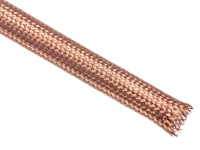

Tinned Copper Braided Sleeving

- Material: M8N Tinned Copper

- Cuts Easily with Scissors

- Highly Abrasion & UV Resistant

- Extreme Blowout Protection

- Meets QQ-B-575B

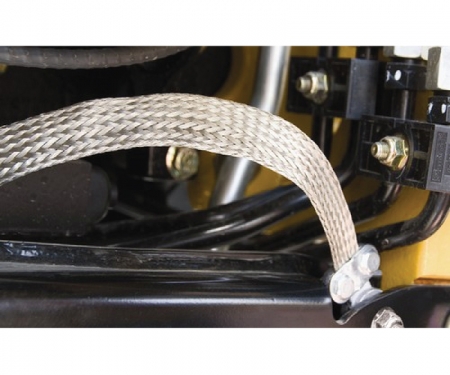

- Can be Used as Grounding Straps

- EMI, RFI, ESD Protection

- Resists Common Chemicals & Solvents

- Will Not Retain Moisture

- Full Coverage for Full Protection

- RoHS Complaint

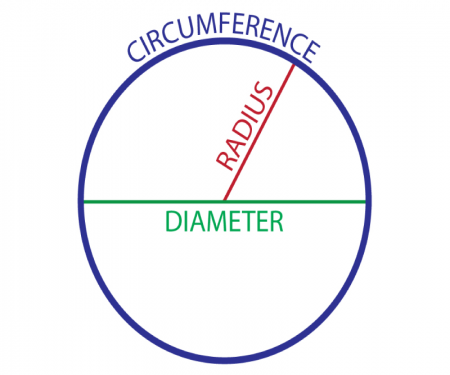

- Inside Diameters Are Measured as Round Not Flat

(Previously known as Metal Braid) the engineer's skill with braided sleeving extends to many materials including tinned copper braided sleeving for a variety of applications. Our tinned copper braid is perfect for shielding on harnesses and cables. wire conforms to ASTM-B 33. Braided from tin-coated copper, it is both flexible and strong, with superior EMI protection. EMI/RFI is commonly referred to as electrical noise. Tinned copper braid is an ideal shielding material for short-run cables. It can provide added shielding in retrofit applications and is much more flexible than foil solutions. Tinned copper braided sleeving provides superior attenuation of greater than 60 dB over wide frequencies, ranging from a few kilohertz (kHz) to several gigahertz (gHz). Tinned Copper Braided sleeving provides ease of installation compared to foil-wrapped cable. High-end automotive, heavy equipment and industrial applications have always used braided metal sleeving for secure and efficient grounding solutions. Our braided tinned copper sleeving is a perfect combination of economy and durability and will provide many years of use even in exposed applications. When installed, Metal Braid provides full coverage and is great for covering and protecting hoses on hot rods and motorcycles.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Wire Thickness | Wires/ Carrier | Cap. Amps | Spool Put-Ups | Lbs/ 100' | |

| Bulk | Shop | |||||||

| 1/16" | MBN0.06SV | 0.013” | 0.005” | 2 | 11 | 250' | 100' | 0.4 |

| *7/64" | MBN0.11SV | 0.013” | 0.005” | 4 | 19 | 250' | 100' | 0.8 |

| 1/8" | MBN0.13SV | 0.013” | 0.005” | 5 | 25 | 250' | 100' | 1.3 |

| *5/32" | MBN0.16SV | 0.013” | 0.005” | 10 | 40 | 250' | 100' | 2.1 |

| *13/64" | MBN0.20SV | 0.020” | 0.008” | 5 | 46 | 250' | 100' | 2.5 |

| *1/4" | MBN0.25SV | 0.013” | 0.005” | 16 | 53 | 250' | 100' | 2.2 |

| *3/8" | MBN0.38SV | 0.013” | 0.005” | 8 | 53 | 250' | 100' | 3.3 |

| *1/2" | MBN0.50SV | 0.013” | 0.005” | 11 | 62 | 250' | 100' | 3.5 |

| 5/8" | MBN0.63SV | 0.016” | 0.006” | 8 | 64 | 100' | 50' | 3.6 |

| *25/32" | MBN0.78SV | 0.013” | 0.005” | 18 | 88 | 100' | 50' | 7.3 |

| *7/8" | MBN0.88SV | 0.025” | 0.010” | 7 | 100 | 100' | 50' | 10.3 |

| *1" | MBN1.00SV | 0.025” | 0.010” | 8 | 120 | 100' | 50' | 13.1 |

| *1 1/8" | MBN1.13SV | 0.025” | 0.010” | 9 | 130 | 100' | 50' | 13.8 |

| 1 1/4" | MBN1.25SV | 0.025” | 0.010” | 10 | 145 | 100' | 50' | 16.5 |

| *1 3/8" | MBN1.38SV | 0.025” | 0.010” | 11 | 150 | 100' | 50' | 16.9 |

| *1 1/2" | MBN1.50SV | 0.025” | 0.010” | 12 | 165 | 100' | 50' | 18.4 |

| 2" | MBN2.00SV | 0.025” | 0.010” | 14 | 180 | 100' | 50' | 22.70 |

| 2 1/4" | MBN2.25SV | 0.025” | 0.010” | 16 | 190 | 100' | 50' | 23.6 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .005 - .010 |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Shears |

| Colors | 1 |

| Wall Thickness | .013 - .025 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | |

| Abrasion Resistance | Medium |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 2 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | NA |

| CVCM | NA |

| WVR | NA |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | NA |

| Oxygen Index (ASTM D-2863) | NA |

| Operating Temperatures | |

| Melt (ASTM D-2117) | 449°F/232°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | No |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

(Previously known as Metal Braid) the engineer's skill with braided sleeving extends to many materials including tinned copper braided sleeving for a variety of applications. Our tinned copper braid is perfect for shielding on harnesses and cables. wire conforms to ASTM-B 33. Braided from tin-coated copper, it is both flexible and strong, with superior EMI protection. EMI/RFI is commonly referred to as electrical noise. Tinned copper braid is an ideal shielding material for short-run cables. It can provide added shielding in retrofit applications and is much more flexible than foil solutions. Tinned copper braided sleeving provides superior attenuation of greater than 60 dB over wide frequencies, ranging from a few kilohertz (kHz) to several gigahertz (gHz). Tinned Copper Braided sleeving provides ease of installation compared to foil-wrapped cable. High-end automotive, heavy equipment and industrial applications have always used braided metal sleeving for secure and efficient grounding solutions. Our braided tinned copper sleeving is a perfect combination of economy and durability and will provide many years of use even in exposed applications. When installed, Metal Braid provides full coverage and is great for covering and protecting hoses on hot rods and motorcycles.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Wire Thickness | Wires/ Carrier | Cap. Amps | Spool Put-Ups | Lbs/ 100' | |

| Bulk | Shop | |||||||

| 1/16" | MBN0.06SV | 0.013” | 0.005” | 2 | 11 | 250' | 100' | 0.4 |

| *7/64" | MBN0.11SV | 0.013” | 0.005” | 4 | 19 | 250' | 100' | 0.8 |

| 1/8" | MBN0.13SV | 0.013” | 0.005” | 5 | 25 | 250' | 100' | 1.3 |

| *5/32" | MBN0.16SV | 0.013” | 0.005” | 10 | 40 | 250' | 100' | 2.1 |

| *13/64" | MBN0.20SV | 0.020” | 0.008” | 5 | 46 | 250' | 100' | 2.5 |

| *1/4" | MBN0.25SV | 0.013” | 0.005” | 16 | 53 | 250' | 100' | 2.2 |

| *3/8" | MBN0.38SV | 0.013” | 0.005” | 8 | 53 | 250' | 100' | 3.3 |

| *1/2" | MBN0.50SV | 0.013” | 0.005” | 11 | 62 | 250' | 100' | 3.5 |

| 5/8" | MBN0.63SV | 0.016” | 0.006” | 8 | 64 | 100' | 50' | 3.6 |

| *25/32" | MBN0.78SV | 0.013” | 0.005” | 18 | 88 | 100' | 50' | 7.3 |

| *7/8" | MBN0.88SV | 0.025” | 0.010” | 7 | 100 | 100' | 50' | 10.3 |

| *1" | MBN1.00SV | 0.025” | 0.010” | 8 | 120 | 100' | 50' | 13.1 |

| *1 1/8" | MBN1.13SV | 0.025” | 0.010” | 9 | 130 | 100' | 50' | 13.8 |

| 1 1/4" | MBN1.25SV | 0.025” | 0.010” | 10 | 145 | 100' | 50' | 16.5 |

| *1 3/8" | MBN1.38SV | 0.025” | 0.010” | 11 | 150 | 100' | 50' | 16.9 |

| *1 1/2" | MBN1.50SV | 0.025” | 0.010” | 12 | 165 | 100' | 50' | 18.4 |

| 2" | MBN2.00SV | 0.025” | 0.010” | 14 | 180 | 100' | 50' | 22.70 |

| 2 1/4" | MBN2.25SV | 0.025” | 0.010” | 16 | 190 | 100' | 50' | 23.6 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .005 - .010 |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Shears |

| Colors | 1 |

| Wall Thickness | .013 - .025 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | |

| Abrasion Resistance | Medium |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 2 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | NA |

| CVCM | NA |

| WVR | NA |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | NA |

| Oxygen Index (ASTM D-2863) | NA |

| Operating Temperatures | |

| Melt (ASTM D-2117) | 449°F/232°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | No |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.