Techflex® Nylon Monofilament Braided Cable Sleeving

High Abrasion & Chemical Resistance - by Techflex

0.0 / 5

Nylon Monofilament Braided Sleeving Features

- Material: Nylon 6-6 Polyamide

- Color: Black

- Cuts Easily with Hot Knife

- Very High Abrasion Resistance

- Expands Up to 150%

- Halogen Free - RoHS Compliant

- Resists Common Chemicals & Solvents

- Dense Braid for Fuller Coverage

- Operating Temperature Range -49° to 302°F (-45° to 150°C)

- Melt Temp 493°F / 256°C

Require Splice Free? Please Call 1-877-284-7760

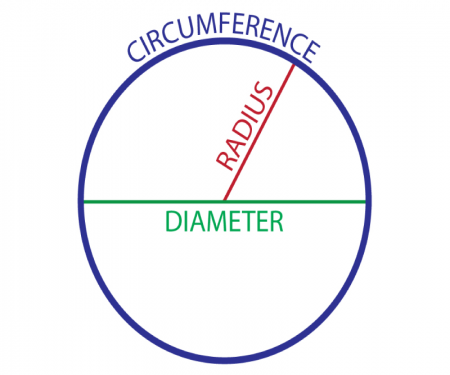

Inside Diameters Are Measured as Round Not Flat

Nylon Monofilament braided sleeving by tech flex is commonly used in the automotive industry to protect hoses and wires from excessive wear. Vibration and movement can tear automotive hoses to pieces, but Nylon monofilament sleeving can increase hose life up to 300%. This lengthened life span is recognized in terms of reduced maintenance; a professional, attractive, and durable appearance, and greater customer satisfaction. Nylon monofilament sleeving is braided from RoHS compliant 12 mil Nylon 6-6 polyamide monofilament. Nylon monofilament braided sleeving provides full coverage, high abrasion resistant sleeving for assemblies exposed to excessive wear.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | |||

| 1/8" 1/4" 3/8" 1/2" 5/8" 3/4" 1" 1 1/4" 1 1/2" 2" | NYN0.13BK NYN0.25BK NYN0.38BK NYN0.50BK NYN0.63BK NYN0.75BK NYN1.00BK NYN1.25BK NYN1.50BK NYN2.00BK | 3/32" 1/8" 1/4" 3/8" 7/16" 1/2" 5/8" 3/4" 1" 1 1/2" | 1/4" 3/8" 7/16" 3/4" 1" 1 1/4" 1 3/8" 1 1/2" 2" 3" | 1,000' 1,000' 500' 500' 500' 250' 250' 250' 200' 200' | 225' 200' 125' 100' 100' 75' 50' 50' 40' 50' | 0.22 0.31 0.72 1.03 1.12 1.47 1.60 1.78 2.55 2.26 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .012 |

| Flammability Rating | |

| Recommended Cutting | Hot Knife |

| Colors | 1 |

| Wall Thickness | .03 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 10.5 |

| Abrasion Resistance | High |

| Specific Gravity | 1.14 |

| Moisture Absorption % (ASTM D-570) | 2.5 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 1.10 |

| CVCM | .01 |

| WVR | .69 |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 22 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 3 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -49°F/-45°C |

| Maximum Continuous (MIL-I-23053) | 302°F/150°C |

| Melt (ASTM D-2117) | 493°F/256°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | No |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Nylon Monofilament braided sleeving by tech flex is commonly used in the automotive industry to protect hoses and wires from excessive wear. Vibration and movement can tear automotive hoses to pieces, but Nylon monofilament sleeving can increase hose life up to 300%. This lengthened life span is recognized in terms of reduced maintenance; a professional, attractive, and durable appearance, and greater customer satisfaction. Nylon monofilament sleeving is braided from RoHS compliant 12 mil Nylon 6-6 polyamide monofilament. Nylon monofilament braided sleeving provides full coverage, high abrasion resistant sleeving for assemblies exposed to excessive wear.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | |||

| 1/8" 1/4" 3/8" 1/2" 5/8" 3/4" 1" 1 1/4" 1 1/2" 2" | NYN0.13BK NYN0.25BK NYN0.38BK NYN0.50BK NYN0.63BK NYN0.75BK NYN1.00BK NYN1.25BK NYN1.50BK NYN2.00BK | 3/32" 1/8" 1/4" 3/8" 7/16" 1/2" 5/8" 3/4" 1" 1 1/2" | 1/4" 3/8" 7/16" 3/4" 1" 1 1/4" 1 3/8" 1 1/2" 2" 3" | 1,000' 1,000' 500' 500' 500' 250' 250' 250' 200' 200' | 225' 200' 125' 100' 100' 75' 50' 50' 40' 50' | 0.22 0.31 0.72 1.03 1.12 1.47 1.60 1.78 2.55 2.26 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .012 |

| Flammability Rating | |

| Recommended Cutting | Hot Knife |

| Colors | 1 |

| Wall Thickness | .03 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 10.5 |

| Abrasion Resistance | High |

| Specific Gravity | 1.14 |

| Moisture Absorption % (ASTM D-570) | 2.5 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 1.10 |

| CVCM | .01 |

| WVR | .69 |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 22 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 3 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -49°F/-45°C |

| Maximum Continuous (MIL-I-23053) | 302°F/150°C |

| Melt (ASTM D-2117) | 493°F/256°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | No |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.