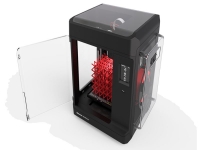

Makerbot METHOD X Carbon Fiber 3D Printer

Print Complex & Durable ABS Parts With a 100°C Heated Chamber

0.0 / 5

Makerbot METHOD X Carbon Fiber 3D Printer Features

MakerBot Method X Carbon Fiber Edition allows you to print carbon fiber reinforced nylon and other engineering-grade composite parts with three-dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

Strong, Heat-Resistant Metal Replacement Parts

Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

- Excellent strength to weight ratio - 110 MPa TS - for lightweighting applications such as robotic end effectors

- Engineering-grade stiffness - 7600 MPa Tensile Modulus - for structural applications such as vehicular brackets and inspection gauges

- High heat resistance under load - 184°C HDT - for optimal under-hood and tooling applications

Superior Nylon Carbon Fiber Parts with METHOD

METHOD’s unique industrial feature set produces carbon fiber parts with superior three dimensional strength and accuracy

- METHOD’s Heated Chamber delivers parts that are strong and accurate.

- Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

- Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

- METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

MakerBot Method X Carbon Fiber Edition

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

Strong, Heat-Resistant Metal Replacement Parts

- Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

- Excellent strength to weight ratio - 110 MPa TS - for lightweighting applications such as robotic end effectors

- Engineering-grade stiffness - 7600 MPa Tensile Modulus - for structural applications such as vehicular brackets and inspection gauges

- High heat resistance under load - 184°C HDT - for optimal under-hood and tooling applications

Superior Nylon Carbon Fiber Parts with METHOD X

- METHOD’s unique industrial feature set produces carbon fiber parts with superior three dimensional strength and accuracy

- METHOD’s Heated Chamber delivers parts that are strong and accurate.

- Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

- Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

- METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

PRINT COMPLEX AND DURABLE ABS PARTS WITH A 100°C HEATED CHAMBER FOR END-USE ASSEMBLIES AND MANUFACTURING TOOLS

Extruder Compatibility

- Model Material Extruders

- Compsite Extruder 1C (included)

- Model 1*

- Model 1XA*

- MB Labs Experimental Extruder*

Support Material Extruders

- Support 2 (included)

- Support 2XA (included)

*sold separately

Model and Support Material Compatibility

- Model Material

- Nylon Carbon Fiber

- ABS

- PC-ABS and PC-ABS Fire Retardant

- PLA

- Tough

- PET-G

- Nylon

Open materials**

Support Material

- SR-30

- PVA

**requires MB Labs Experimental Extruder

Method Specs:

Print Technology

Fused Deposition Modeling (FDM)

Print Heads

2

Dimensional Accuracy

± 0.2 mm1

Layer Resolution

Range: 20 - 400 microns

Build Speed

Up to 2x faster than desktop 3D printers2

Max Material Flow Rate: ~50 mm3 per sec

Print Head Travel Speed: Up to 500 mm per sec

Print modes tuned and optimized for:

100 microns - High Quality Print Mode (Coming Soon)

200 microns - Balanced Print Mode

Maximum Build Volume

19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion (print settings coming soon)

15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion

WHAT'S IN THE BOX:

- 1 MakerBot METHOD X 3D Printer

- 1 Spring Steel Build Plate

- 1 Composite Extruder

- 1 Performance Extruder 2XA Support

- 1 Performance Extruder 2 Support

- 1 Nozzle Brush

- 1 Hex Key

- 1 USB A-to-B Cable

- 1 US Power Cord

- 1 EU Power Cord

Please note: MakerBot materials sold separately.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

MakerBot Method X Carbon Fiber Edition

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

Strong, Heat-Resistant Metal Replacement Parts

- Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

- Excellent strength to weight ratio - 110 MPa TS - for lightweighting applications such as robotic end effectors

- Engineering-grade stiffness - 7600 MPa Tensile Modulus - for structural applications such as vehicular brackets and inspection gauges

- High heat resistance under load - 184°C HDT - for optimal under-hood and tooling applications

Superior Nylon Carbon Fiber Parts with METHOD X

- METHOD’s unique industrial feature set produces carbon fiber parts with superior three dimensional strength and accuracy

- METHOD’s Heated Chamber delivers parts that are strong and accurate.

- Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

- Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

- METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

PRINT COMPLEX AND DURABLE ABS PARTS WITH A 100°C HEATED CHAMBER FOR END-USE ASSEMBLIES AND MANUFACTURING TOOLS

Extruder Compatibility

- Model Material Extruders

- Compsite Extruder 1C (included)

- Model 1*

- Model 1XA*

- MB Labs Experimental Extruder*

Support Material Extruders

- Support 2 (included)

- Support 2XA (included)

*sold separately

Model and Support Material Compatibility

- Model Material

- Nylon Carbon Fiber

- ABS

- PC-ABS and PC-ABS Fire Retardant

- PLA

- Tough

- PET-G

- Nylon

Open materials**

Support Material

- SR-30

- PVA

**requires MB Labs Experimental Extruder

Method Specs:

Print Technology

Fused Deposition Modeling (FDM)

Print Heads

2

Dimensional Accuracy

± 0.2 mm1

Layer Resolution

Range: 20 - 400 microns

Build Speed

Up to 2x faster than desktop 3D printers2

Max Material Flow Rate: ~50 mm3 per sec

Print Head Travel Speed: Up to 500 mm per sec

Print modes tuned and optimized for:

100 microns - High Quality Print Mode (Coming Soon)

200 microns - Balanced Print Mode

Maximum Build Volume

19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion (print settings coming soon)

15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion

WHAT'S IN THE BOX:

- 1 MakerBot METHOD X 3D Printer

- 1 Spring Steel Build Plate

- 1 Composite Extruder

- 1 Performance Extruder 2XA Support

- 1 Performance Extruder 2 Support

- 1 Nozzle Brush

- 1 Hex Key

- 1 USB A-to-B Cable

- 1 US Power Cord

- 1 EU Power Cord

Please note: MakerBot materials sold separately.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.