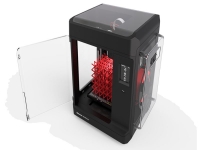

Makerbot METHOD X - ASA Filament

UV & Moisture Resistance For Demanding Outdoor Applications

0.0 / 5

Makerbot METHOD X - ASA Filament Features

- Material Diameter: 1.75 mm

- Net Weight: 0.65 kg (1.43 lb)

- Finished part dimensional accuracy of ± 0.2mm (± 0.007in)1

ASA combines the qualities of ABS with the added benefit of UV resistance and additional moisture resistance making it ideal for equipment exposed to sunlight and rain over long periods of time – such as products for the agriculture, transportation, and power and utility industries.

RINTER COMPATIBILITY

MakerBot METHOD X

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

MATERIAL DATA - ASA

Heat Deflection @ 66 psi - ASTM 648: 96°C (204°F)

Flexural Strength (Method 1, 0.05”/min): 78 MPa (11,000 psi)

Flexural Modulus (Method 1, 0.05”/min): 2300 MPa (330,000 psi)

Tensile Strength at yield (Type 1, 0.125”, 0.2”/min): 49 MPa (7,100psi)

Tensile Modulus (ISO 527): 2,100 MPa (310,000 psi)

Strain at Yield - Elongation (%): >6%

Notched Impact Strength (ASTM D256): 140 J/m (2.6 ft-lb/in)

DIMENSIONS AND WEIGHT

Spool Diameter: 21.8 cm (8.6 in)

Spool Width: 4.2 cm (1.65 in)

Material Diameter: 1.75 mm

Shipping Weight: 1.1 kg (2.4 lb)

Net Weight: 0.65 kg (1.43 lb)

STORAGE ENVIRONMENT

Store in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

END-USE PARTS

Engineers and machinists can create functional end-use parts with durability and ductility including snap fits and living hinges capable of withstanding the elements. Applications include:

• Industrial machine covers

• Protective guards

• Outdoor signage

• Replacement parts for agriculture

FUNCTIONAL PROTOTYPES

Designers and engineers can create functional prototypes that combine superior part durability with temperature, moisture, and chemical resistance in demanding outdoor conditions. Applications include:

• Sporting goods and accessories

• All-weather assembly housings

• Enclosures for outdoor electrical equipment

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| TECH SPECS | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 204°F | 96°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 330,000 psi | 2,300 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 7100 psi | 49 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | 310,000 psi | 2,100 MPa |

| Strain at Yield - Elongation (%) | >6% | >6% |

| Notched Impact Strength (ASTM D256) | 2.6 ft-lb/in | 140 J/m |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

RINTER COMPATIBILITY

MakerBot METHOD X

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

MATERIAL DATA - ASA

Heat Deflection @ 66 psi - ASTM 648: 96°C (204°F)

Flexural Strength (Method 1, 0.05”/min): 78 MPa (11,000 psi)

Flexural Modulus (Method 1, 0.05”/min): 2300 MPa (330,000 psi)

Tensile Strength at yield (Type 1, 0.125”, 0.2”/min): 49 MPa (7,100psi)

Tensile Modulus (ISO 527): 2,100 MPa (310,000 psi)

Strain at Yield - Elongation (%): >6%

Notched Impact Strength (ASTM D256): 140 J/m (2.6 ft-lb/in)

DIMENSIONS AND WEIGHT

Spool Diameter: 21.8 cm (8.6 in)

Spool Width: 4.2 cm (1.65 in)

Material Diameter: 1.75 mm

Shipping Weight: 1.1 kg (2.4 lb)

Net Weight: 0.65 kg (1.43 lb)

STORAGE ENVIRONMENT

Store in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

END-USE PARTS

Engineers and machinists can create functional end-use parts with durability and ductility including snap fits and living hinges capable of withstanding the elements. Applications include:

• Industrial machine covers

• Protective guards

• Outdoor signage

• Replacement parts for agriculture

FUNCTIONAL PROTOTYPES

Designers and engineers can create functional prototypes that combine superior part durability with temperature, moisture, and chemical resistance in demanding outdoor conditions. Applications include:

• Sporting goods and accessories

• All-weather assembly housings

• Enclosures for outdoor electrical equipment

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| TECH SPECS | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 204°F | 96°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 330,000 psi | 2,300 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 7100 psi | 49 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | 310,000 psi | 2,100 MPa |

| Strain at Yield - Elongation (%) | >6% | >6% |

| Notched Impact Strength (ASTM D256) | 2.6 ft-lb/in | 140 J/m |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.