Makerbot® METHOD X ABS Filament

Production grade ABS filament can withstand temperatures up to 183°F

0.0 / 5

Makerbot® METHOD X ABS Filament Features

-

Finished part dimensional accuracy of ± 0.2mm (± 0.007in)1

-

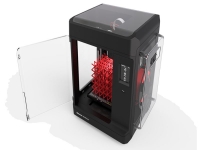

For METHOD X 3D Printer

-

1 x Spool of ABS Filament

-

Strong, Rigid Material

- Smart Spool

Optimized for the MakerBot METHOD X 3D printer, this spool of black True Color ABS Filament is designed to bring your printed projects to life with strength and precision. Designed for manufacturing tools and end-use parts, the production-grade ABS filament can withstand temperatures up to 183°F and features a 348,000 psi tensile modulus for high rigidity with a tensile strength of 0.806 psi. The Smart Spool includes an integrated RFID chip that transmits information to the printer, including the material type, color, and amount remaining. The spool also has desiccant, which helps to maintain low moisture levels inside the drawer bay.

END-USE PARTS Custom parts, low volume production, and components that require high geometric complexity Applications include:

- Liquid containers

- Signage and graphic displays

- Enclosures for electrical equipment

MANUFACTURING TOOLS Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor Applications include:

- Manufacturing tools and aids

- Robotic end effectors

- Product testing tools

FUNCTIONAL PROTOTYPES Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part

Applications include:

- Consumer product prototypes

- Appliance assemblies

- Automotive parts

PRINTER COMPATIBILITY

MakerBot METHOD X

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

MATERIAL DATA

Heat Deflection @ 66 psi - ASTM 648: 84°C (183°F)

Flexural Strength (Method 1, 0.05”/min): 65 MPa (9,427 psi)

Flexural Modulus (Method 1, 0.05”/min): 77 Mpa (11,200 psi)

Tensile Strength at yield ((Type 1, 0.125”, 0.2”/min): 43 Mpa (6,236 psi)

Tensile Modulus (ISO 527): 2,400 MPa (348,090 psi)

Strain at Yield - Elongation (%): 2.6%

Notched Impact Strength (ASTM D256): 26 J/m (0.48 ft-lb/in)

DIMENSIONS AND WEIGHT

Spool Diameter: 21.8 cm (8.6 in)

Spool Width: 4.2 cm (1.65 in)

Material Diameter: 1.75 mm

Shipping Weight: 1.1 kg (2.4 lb)

Net Weight: 0.65 kg (1.43 lb)

STORAGE ENVIRONMENT

Store in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| TECH SPECS | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 210°F | 99°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 377,000 psi | 2,600 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 0.806 psi | 43 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | 348,000 psi | 2,400 MPa |

| Strain at Yield - Elongation (%) | >5.6% | >5.6% |

| Notched Impact Strength (ASTM D256) | 3.6 ft-lb/in |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

END-USE PARTS Custom parts, low volume production, and components that require high geometric complexity Applications include:

- Liquid containers

- Signage and graphic displays

- Enclosures for electrical equipment

MANUFACTURING TOOLS Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor Applications include:

- Manufacturing tools and aids

- Robotic end effectors

- Product testing tools

FUNCTIONAL PROTOTYPES Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part

Applications include:

- Consumer product prototypes

- Appliance assemblies

- Automotive parts

PRINTER COMPATIBILITY

MakerBot METHOD X

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

MATERIAL DATA

Heat Deflection @ 66 psi - ASTM 648: 84°C (183°F)

Flexural Strength (Method 1, 0.05”/min): 65 MPa (9,427 psi)

Flexural Modulus (Method 1, 0.05”/min): 77 Mpa (11,200 psi)

Tensile Strength at yield ((Type 1, 0.125”, 0.2”/min): 43 Mpa (6,236 psi)

Tensile Modulus (ISO 527): 2,400 MPa (348,090 psi)

Strain at Yield - Elongation (%): 2.6%

Notched Impact Strength (ASTM D256): 26 J/m (0.48 ft-lb/in)

DIMENSIONS AND WEIGHT

Spool Diameter: 21.8 cm (8.6 in)

Spool Width: 4.2 cm (1.65 in)

Material Diameter: 1.75 mm

Shipping Weight: 1.1 kg (2.4 lb)

Net Weight: 0.65 kg (1.43 lb)

STORAGE ENVIRONMENT

Store in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| TECH SPECS | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 210°F | 99°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 377,000 psi | 2,600 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 0.806 psi | 43 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | 348,000 psi | 2,400 MPa |

| Strain at Yield - Elongation (%) | >5.6% | >5.6% |

| Notched Impact Strength (ASTM D256) | 3.6 ft-lb/in |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.