Techflex® L6 Liquid Repellant Wrap Cable Sleeving

Wrap-Around Fluid Repellant Protection For Wires & Cables

0.0 / 5

L6 Liquid Wrap Sleeving Features

- Specially designed for Hospitals and other locations that have disinfection protocols.

- Water repellent When Properly Sealed

- Will Not Support Growth of Bacteria

- Disinfects Easily

- Adhesive Resists Most Cleaners & Disinfectants

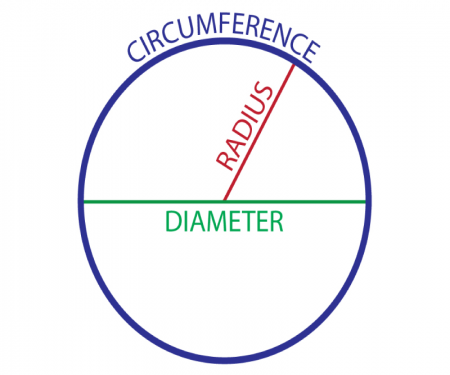

Inside Diameters Are Measured as Round Not Flat

L6 Liquid Wrap semi-rigid wrap-around sleeving is engineered from tough braided polyester and laminated with a layer of strong Mylar sheeting. This combination provides a strong and lightweight solution for any application that requires protection from repeated exposure to the elements.

The wrap-around construction, with 12% edge overlap makes installation easy over existing assemblies or harnesses, and the extra-wide adhesive strip ensures a positive, aggressive seal against damage from exposure.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | 8' Pcs. Put-Ups | Available Colors | Lbs/ 10Pcs. | |||

| Bulk Box | Box 8x8 | Box 6x6 | Box 4x4 | |||||

| 3/8" 1/2" 3/4" 1" 1 1/4" | L6N0.38 L6N0.50 L6N0.75 L6N1.00 L6N1.25 | .046" .046" .046" .046" .046" | 125 125 60 44 30 | 45 35 25 15 10 | 25 20 15 10 5 | 15 12 5 4 3 | BK BK BK BK BK | 1.8 2.0 3.6 4.4 5.2 |

| Physical Properties | |

| Recommended Cutting | Scissor |

| Colors | 2 |

| Wall Thickness | .046 |

| Specific Gravity | 1.38 |

| Moisture Absorption | .1-.2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 3 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 2 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | Yes |

| SVHC | None |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

L6 Liquid Wrap semi-rigid wrap-around sleeving is engineered from tough braided polyester and laminated with a layer of strong Mylar sheeting. This combination provides a strong and lightweight solution for any application that requires protection from repeated exposure to the elements.

The wrap-around construction, with 12% edge overlap makes installation easy over existing assemblies or harnesses, and the extra-wide adhesive strip ensures a positive, aggressive seal against damage from exposure.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | 8' Pcs. Put-Ups | Available Colors | Lbs/ 10Pcs. | |||

| Bulk Box | Box 8x8 | Box 6x6 | Box 4x4 | |||||

| 3/8" 1/2" 3/4" 1" 1 1/4" | L6N0.38 L6N0.50 L6N0.75 L6N1.00 L6N1.25 | .046" .046" .046" .046" .046" | 125 125 60 44 30 | 45 35 25 15 10 | 25 20 15 10 5 | 15 12 5 4 3 | BK BK BK BK BK | 1.8 2.0 3.6 4.4 5.2 |

| Physical Properties | |

| Recommended Cutting | Scissor |

| Colors | 2 |

| Wall Thickness | .046 |

| Specific Gravity | 1.38 |

| Moisture Absorption | .1-.2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 3 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 2 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| UL/CSA | Yes |

| SVHC | None |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.