Techflex® Flexo® Kevlar Braided Cable Sleeving

Stronger Than Steel Yet Still Soft & Pliable - Will Not Melt or Burn

0.0 / 5

Kevlar Braided Sleeving Features

- Material: Kevlar Aramid Fibers

- Color: Yellow

- Up To 20 Times Stronger Than Steel

- Dense Braid For Full Coverage

- Operating Temps: -274°F to 320°F (-170°C to 160°C)

- Will Not Melt, Burn or Support Combustion

- Stays Soft & Pliable

- Resists Acids, Bases, Solvents, & Fuels

- Excellent Abrasion Resistance

- Cuts With Flexo Aramid Shears

*Flexo KV is degraded by ultraviolet light.*

Require Splice Free? Please Call 1-877-284-7760

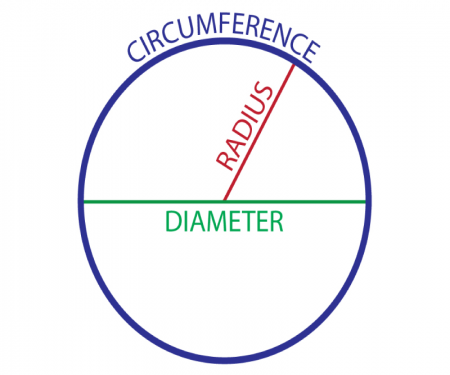

Inside Diameters Are Measured as Round Not Flat

Kevlar braided sleeving provides extreme strength and durability, yet is lightweight and easy to install.

Flexo Kevlar braided sleeving is a soft, flexible cable sleeving that’s perfect for bundling and protecting vulnerable components from the most extreme environmental conditions. Kevlar sleeving is braided from aramid fibers and has all of Flexo Kevlar braided sleeving’s well-known characteristics of durability, pliability, and extraordinary tensile strength. Kevlar braided sleeving fibers are up to 20 times stronger than steel fibers of equal diameter. Kevlar braided sleeving has excellent thermal stability, permitting long-term, continuous use at temperatures as low as -274°F and as high as 320°F. Short-term exposure up to 572°F can be tolerated. Flexo Kevlar braided sleeving does not melt or support combustion. Please note that Flexo KV is degraded by ultraviolet light. Do not store in direct sunlight. Fluorescent lighting will cause discoloration, but will not affect fiber mechanical properties.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| 1/4" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | KVN0.25YL KVN0.50YL KVN0.75YL KVN1.00YL KVN1.25YL KVN1.50YL KVN2.00YL | 1/8" 1/4" 1/2" 3/4" 1" 1 1/4" 1 3/4" | 5/16" 5/8" 7/8" 1 1/4" 1 5/8" 2" 2 1/2" | 500' 250' 250' 200' 125' 100' 100' | 50' 50' 50' 25' 25' 25' 25' | 1 1 1 1 1 1 1 | 0.30 0.74 1.44 1.92 2.40 2.90 3.60 |

| Physical Properties | |

| Recommended Cutting | Flexo Aramid Shears |

| Colors | 1 |

| Wall Thickness | .02 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 39 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.44 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 3.13 |

| CVCM | .19 |

| WVR | 1.76 |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 29 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 2 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 2 |

| UV Light | 4 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -274°F/-170°C |

| Maximum Continuous (MIL-I-23053) | 320°F/160°C |

| Other Information | |

| Halogen Free | Yes |

| UL/CSA | No |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Kevlar braided sleeving provides extreme strength and durability, yet is lightweight and easy to install.

Flexo Kevlar braided sleeving is a soft, flexible cable sleeving that’s perfect for bundling and protecting vulnerable components from the most extreme environmental conditions. Kevlar sleeving is braided from aramid fibers and has all of Flexo Kevlar braided sleeving’s well-known characteristics of durability, pliability, and extraordinary tensile strength. Kevlar braided sleeving fibers are up to 20 times stronger than steel fibers of equal diameter. Kevlar braided sleeving has excellent thermal stability, permitting long-term, continuous use at temperatures as low as -274°F and as high as 320°F. Short-term exposure up to 572°F can be tolerated. Flexo Kevlar braided sleeving does not melt or support combustion. Please note that Flexo KV is degraded by ultraviolet light. Do not store in direct sunlight. Fluorescent lighting will cause discoloration, but will not affect fiber mechanical properties.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| 1/4" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | KVN0.25YL KVN0.50YL KVN0.75YL KVN1.00YL KVN1.25YL KVN1.50YL KVN2.00YL | 1/8" 1/4" 1/2" 3/4" 1" 1 1/4" 1 3/4" | 5/16" 5/8" 7/8" 1 1/4" 1 5/8" 2" 2 1/2" | 500' 250' 250' 200' 125' 100' 100' | 50' 50' 50' 25' 25' 25' 25' | 1 1 1 1 1 1 1 | 0.30 0.74 1.44 1.92 2.40 2.90 3.60 |

| Physical Properties | |

| Recommended Cutting | Flexo Aramid Shears |

| Colors | 1 |

| Wall Thickness | .02 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 39 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.44 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 3.13 |

| CVCM | .19 |

| WVR | 1.76 |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 29 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 2 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 2 |

| UV Light | 4 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -274°F/-170°C |

| Maximum Continuous (MIL-I-23053) | 320°F/160°C |

| Other Information | |

| Halogen Free | Yes |

| UL/CSA | No |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.