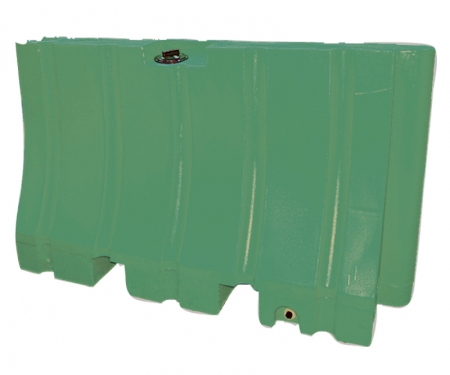

Heavy Duty Plastic Jersey Traffic Barriers

DOT Approved - 72" or 96" Lengths - 6 Colors - Sand & Water Fillable

0.0 / 5

Heavy Duty Plastic Jersey Traffic Barriers Features

- 42” Height

- Available in Orange, White, Yellow, Tan, Olive Drab, or Blue

- Choose from various wall thicknesses

- Compatible with square bolt-on or round screw-in lights

- UV and long-term fade resistant

- Composition: UV-Resistant Polyethylene

- PLEASE CALL FOR VOLUME PRICING FOR FULL TRUCK-LOAD QUANTITIES

42x72x24 plastic jersey barriers have been tested and approved by the US Dept of Transportation. Made from UV-Resistant Polyethylene, this portable and durable safety plastic jersey barrier is structurally sound and impact resistant. It can be easily relocated and reconfigured and is ballast able with sand or water for added stability. It also features built-in molded forklift slots for maximum convenience. Great for road work or parking lot construction projects. The water-filled plastic jersey traffic barrier will not bulge or distort when filled with water ballast or sand. We also will not jeopardize our quality just to sell our barrier. During the design of the plastic jersey barrier, we take into account that cosmetics are also a key selling point in our desired markets. We believe that we have a product that is more cosmetically pleasing than our competitors. This heavy-duty traffic barrier has also been designed to a higher standard of strength and integrity which we feel makes for a superior product for the end-user. as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety Hardware Test Level 2. It was stated to be acceptable as a TL2 water-filled channelizer. We do have a letter with all the testing results if any further questions need to be answered regarding the testing. Most of our barriers now have fill lines. We recommend only filling the barriers to the fill line – overfilling can cause bulging. To keep water from freezing inside our suggestion is to use Calcium Chloride. You use 4-6 oz of Calcium Chloride per gallon depending on the temps outside.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

42x72x24 – Fill Line is 100 gallon of water – total weight is 834 lbs + weight of barrier

42x96x24 – 13” above the parting line is 130 gal. of water – total weight is 1084 lbs + weight of barrier

The 42x72x24 100# barrier has been tested and approved by the US Dept of Transportation

as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety

Hardware Test Level 2. It was stated to be acceptable as a TL2 water filled channelizer.

No Minimum Order Quantity

MADE TO ORDER LEAD TIMES MAY APPLY

Non-Cancellable & Non-Refundable

Products ship LTL FREIGHT ONLY

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

How Does Rotational Molding Work?

Simply stated, rotational molding is a process by which plastic products are manufactured for a variety of applications. The process itself is a molding cycle that goes through four different phases. The first phase is referred to as the charging phase, during this phase material or resin is charged into the mold and the mold is sealed for phase two. During the second phase, the mold is heated to a desired temperature while rotating on two specific axes. The third phase consists of a cooling stage where the mold begins to cool and the plastic begins to solidify and maintain the shape of the mold. Once the plastic resin has cooled long enough to hold its own shape, we enter into the final phase. During this final phase, the mold will be reopened and the part will be de-molded producing a solid plastic product.

2) How Does Rotational Molding Compare In Price To Other Forms of Molding Technologies?

Rotational molding is very competitive when it comes to cost analysis of the different molding technologies. As a comparison, the price of the tooling for rotational molding is very inexpensive compared to some other molding technologies. The prices of individual parts are very comparable to most molding procedures. However, the ability to produce large parts or hollow parts is relatively inexpensive compared to the same products in other molding technologies.

3) What Is a Typical Cycle Time For a Rotational Molded Product?

Cycle time is a major topic in the rotational molding industry. The time of one cycle usually spans between relatively short runs of 15 minutes to a long run time of 1 hour and 30 minutes. The thickness of the product and the machine capabilities often have a major impact on the cycle time. Additional features such as cooling fans and curtains reduce the cycle time as well as advancements in machinery and equipment. Currently, there is research being done to better understand and reduce cycle time in rotational molding.

What Makes Your Safety Barriers Superior To Others On The Market?

These heavy-duty Jersey barriers products are of high quality and different in innovative content and design. These plastic jersey barriers will not bulge or distort when filled with water ballast or sand. Quality is never jeopardized to sell more barriers. During the design of these jersey barriers, we take into account that cosmetics are also a key selling point in our desired markets. We believe that these heavy-duty traffic barriers are more cosmetically pleasing than the competition. These water-fill traffic safety barricades have also been designed to a higher standard of strength and integrity which we feel makes for a superior product for the end-user.

How Much Water Do You Put In The Barriers?

Most traffic jersey barriers now have fill lines. The manufacturer recommends only filling the barriers to the fill line as overfilling can cause bulging.

10x96x10 – Fill line is 17 gallons of water – total weight including barrier 165 lbs

24x96x16 – 7” above parting line is 50 gallons of water – total weight including barrier 467 lbs

Stackable barrier – Fill Line is 50 gallons of water – total weight including barrier 487 lbs

Wedge Barrier – Fill Line is 70 gallons of water – total weight including barrier 653 lbs

32x72x18 – 15” above parting line is 70 gallon of water – total weight including barrier 653 lbs

42x72x24 – Fill Line is 100 gallon of water – total weight is 834 lbs + weight of barrier

42x96x24 – 13” above the parting line is 130 gal. of water – total weight is 1084 lbs + weight of barrier

31x120x24 – Filling ½ full is 80 gallons of water – total weight is 667 lbs + weight of barrier

48” Cont Barrier – Fill Line is 75 gallons of water – total weight including barrier 745 lbs

How Do You Keep The Barriers From Freezing In The Winter?

Our suggestion is using Calcium Chloride. You use 4-6 oz of Calcium Chloride per gallon

depending on the temps outside.

How Many Barriers Fit ON A STANDARD 53’ TRUCKLOAD?

10x96 – 432 barriers – these are always skidded – 36 barriers per skid

24x96 – 208 barriers – these are loaded loose

32x72 – 174 barriers – these are loaded loose

42x72 – 96 barriers – these are loaded loose

42x96 – 75 barriers – these are loaded loose

31x120 – 75 barriers – these are loaded loose

29” Cont Barrier – 150 barriers (approx.) – these are loaded loose

48” Cont Barrier – 78 barriers (approx.) – these are loaded loose

Do Your Barriers Accept Fencing?

Yes, we have a couple of barricades that accept fencing. Our 32x72 & 42x72 barriers are the only 2 barriers we carry that do accept fencing.

Do Any Of Your Barriers Meet TL1, TL2 OR TL3?

The 42x72x24 100# barrier has been tested and approved by the US Dept of Transportation

as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety

Hardware Test Level 2. It was stated to be acceptable as a TL2 water filled channelizer.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

42x72x24 plastic jersey barriers have been tested and approved by the US Dept of Transportation. Made from UV-Resistant Polyethylene, this portable and durable safety plastic jersey barrier is structurally sound and impact resistant. It can be easily relocated and reconfigured and is ballast able with sand or water for added stability. It also features built-in molded forklift slots for maximum convenience. Great for road work or parking lot construction projects. The water-filled plastic jersey traffic barrier will not bulge or distort when filled with water ballast or sand. We also will not jeopardize our quality just to sell our barrier. During the design of the plastic jersey barrier, we take into account that cosmetics are also a key selling point in our desired markets. We believe that we have a product that is more cosmetically pleasing than our competitors. This heavy-duty traffic barrier has also been designed to a higher standard of strength and integrity which we feel makes for a superior product for the end-user. as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety Hardware Test Level 2. It was stated to be acceptable as a TL2 water-filled channelizer. We do have a letter with all the testing results if any further questions need to be answered regarding the testing. Most of our barriers now have fill lines. We recommend only filling the barriers to the fill line – overfilling can cause bulging. To keep water from freezing inside our suggestion is to use Calcium Chloride. You use 4-6 oz of Calcium Chloride per gallon depending on the temps outside.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

42x72x24 – Fill Line is 100 gallon of water – total weight is 834 lbs + weight of barrier

42x96x24 – 13” above the parting line is 130 gal. of water – total weight is 1084 lbs + weight of barrier

The 42x72x24 100# barrier has been tested and approved by the US Dept of Transportation

as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety

Hardware Test Level 2. It was stated to be acceptable as a TL2 water filled channelizer.

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

How Does Rotational Molding Work?

Simply stated, rotational molding is a process by which plastic products are manufactured for a variety of applications. The process itself is a molding cycle that goes through four different phases. The first phase is referred to as the charging phase, during this phase material or resin is charged into the mold and the mold is sealed for phase two. During the second phase, the mold is heated to a desired temperature while rotating on two specific axes. The third phase consists of a cooling stage where the mold begins to cool and the plastic begins to solidify and maintain the shape of the mold. Once the plastic resin has cooled long enough to hold its own shape, we enter into the final phase. During this final phase, the mold will be reopened and the part will be de-molded producing a solid plastic product.

2) How Does Rotational Molding Compare In Price To Other Forms of Molding Technologies?

Rotational molding is very competitive when it comes to cost analysis of the different molding technologies. As a comparison, the price of the tooling for rotational molding is very inexpensive compared to some other molding technologies. The prices of individual parts are very comparable to most molding procedures. However, the ability to produce large parts or hollow parts is relatively inexpensive compared to the same products in other molding technologies.

3) What Is a Typical Cycle Time For a Rotational Molded Product?

Cycle time is a major topic in the rotational molding industry. The time of one cycle usually spans between relatively short runs of 15 minutes to a long run time of 1 hour and 30 minutes. The thickness of the product and the machine capabilities often have a major impact on the cycle time. Additional features such as cooling fans and curtains reduce the cycle time as well as advancements in machinery and equipment. Currently, there is research being done to better understand and reduce cycle time in rotational molding.

What Makes Your Safety Barriers Superior To Others On The Market?

These heavy-duty Jersey barriers products are of high quality and different in innovative content and design. These plastic jersey barriers will not bulge or distort when filled with water ballast or sand. Quality is never jeopardized to sell more barriers. During the design of these jersey barriers, we take into account that cosmetics are also a key selling point in our desired markets. We believe that these heavy-duty traffic barriers are more cosmetically pleasing than the competition. These water-fill traffic safety barricades have also been designed to a higher standard of strength and integrity which we feel makes for a superior product for the end-user.

How Much Water Do You Put In The Barriers?

Most traffic jersey barriers now have fill lines. The manufacturer recommends only filling the barriers to the fill line as overfilling can cause bulging.

10x96x10 – Fill line is 17 gallons of water – total weight including barrier 165 lbs

24x96x16 – 7” above parting line is 50 gallons of water – total weight including barrier 467 lbs

Stackable barrier – Fill Line is 50 gallons of water – total weight including barrier 487 lbs

Wedge Barrier – Fill Line is 70 gallons of water – total weight including barrier 653 lbs

32x72x18 – 15” above parting line is 70 gallon of water – total weight including barrier 653 lbs

42x72x24 – Fill Line is 100 gallon of water – total weight is 834 lbs + weight of barrier

42x96x24 – 13” above the parting line is 130 gal. of water – total weight is 1084 lbs + weight of barrier

31x120x24 – Filling ½ full is 80 gallons of water – total weight is 667 lbs + weight of barrier

48” Cont Barrier – Fill Line is 75 gallons of water – total weight including barrier 745 lbs

How Do You Keep The Barriers From Freezing In The Winter?

Our suggestion is using Calcium Chloride. You use 4-6 oz of Calcium Chloride per gallon

depending on the temps outside.

How Many Barriers Fit ON A STANDARD 53’ TRUCKLOAD?

10x96 – 432 barriers – these are always skidded – 36 barriers per skid

24x96 – 208 barriers – these are loaded loose

32x72 – 174 barriers – these are loaded loose

42x72 – 96 barriers – these are loaded loose

42x96 – 75 barriers – these are loaded loose

31x120 – 75 barriers – these are loaded loose

29” Cont Barrier – 150 barriers (approx.) – these are loaded loose

48” Cont Barrier – 78 barriers (approx.) – these are loaded loose

Do Your Barriers Accept Fencing?

Yes, we have a couple of barricades that accept fencing. Our 32x72 & 42x72 barriers are the only 2 barriers we carry that do accept fencing.

Do Any Of Your Barriers Meet TL1, TL2 OR TL3?

The 42x72x24 100# barrier has been tested and approved by the US Dept of Transportation

as a Test Level 2 Longitudinal Channelizing Device – AASHTO Manual for Assessing Safety

Hardware Test Level 2. It was stated to be acceptable as a TL2 water filled channelizer.

Videos

No Minimum Order Quantity

MADE TO ORDER LEAD TIMES MAY APPLY

Non-Cancellable & Non-Refundable

Products ship LTL FREIGHT ONLY