Techflex® Insultherm® Header Exhaust Braided Cable Wrap

Insulates Exhausts For Increased Horsepower - Resists 1,200°F Heat

0.0 / 5

Insultherm Header Exhaust Wrap Features

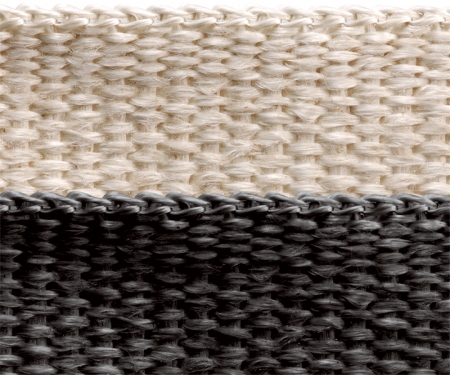

- Texturized Fiberglass or Silica Fiber Construction

- Operating Temperature Range -70° to 1200°F (-57° to 649 °C.)

- Extremely Abrasion and Cut Resistant

- Will Not Burn or Support Combustion

- Resists Common Chemicals & Solvents

- Easy, No Tool Installation

- RoHS Compliant

- Cuts Easily With Scissors

- Protects Up To 2,000°F.

- 2,048°F / 1,120°C. Melt Temp

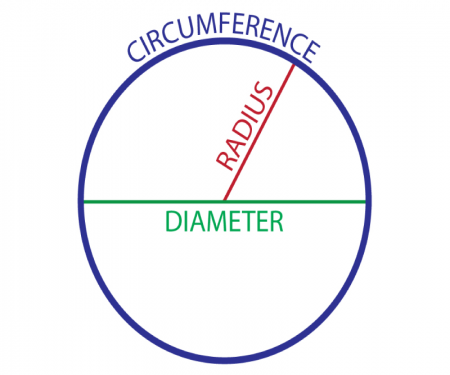

Inside Diameters Are Measured as Round Not Flat

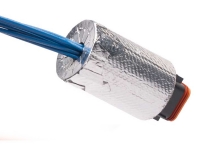

Insultherm Header Wrap is an extremely high temperature resistant wrap commonly used to contain and manage hot gases in automotive and high performance headers and exhausts. Header Wrap is manufactured from texturized fiberglass yarns that are woven into a strong and flexible wrap with vermiculite coating. Remember when it comes to exhaust wrap, overlapping 1/4” is perfect as this allows just enough heat out to ensure performance without damaging your exhaust

Installation Process

Before installing Header Wrap, soak the entire length of material in water until it's fully saturated. Wrap the wet material around your pipes, remembering to overlap the edges slighty for full coverage. At the ends, secure the wrap with stainless steel cable ties. When your pipes warm up, the moisture will evaporate and the wrap will shrink slightly to form a tight protective seal around the entire assembly.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thick. | Widths | Max Cont. Temp. | Standard Spool Put-Ups | Lbs/ 100' | ||

| Bulk 1 | Bulk 2 | Bulk 3 | ||||||

| 1" 2" | HFN1.00 HFN2.00 | 1/16" 1/16" | 1" 2" | 1,000°F | 100' 100' | 50' 50' | 25' 25' | 1.50 3.05 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | NA |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Scissor |

| Colors | 2 |

| Wall Thickness | .0625 - .125 |

| Specific Gravity | 2.6 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 1 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Maximum Continuous (MIL-I-23053) | 1,200°F/649°C |

| Melt (ASTM D-2117) | 2,048°F/1,120°C |

| Other Information | |

| UL/CSA | Yes |

| Halogen Free | Yes |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Insultherm Header Wrap is an extremely high temperature resistant wrap commonly used to contain and manage hot gases in automotive and high performance headers and exhausts. Header Wrap is manufactured from texturized fiberglass yarns that are woven into a strong and flexible wrap with vermiculite coating. Remember when it comes to exhaust wrap, overlapping 1/4” is perfect as this allows just enough heat out to ensure performance without damaging your exhaust

Installation Process

Before installing Header Wrap, soak the entire length of material in water until it's fully saturated. Wrap the wet material around your pipes, remembering to overlap the edges slighty for full coverage. At the ends, secure the wrap with stainless steel cable ties. When your pipes warm up, the moisture will evaporate and the wrap will shrink slightly to form a tight protective seal around the entire assembly.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thick. | Widths | Max Cont. Temp. | Standard Spool Put-Ups | Lbs/ 100' | ||

| Bulk 1 | Bulk 2 | Bulk 3 | ||||||

| 1" 2" | HFN1.00 HFN2.00 | 1/16" 1/16" | 1" 2" | 1,000°F | 100' 100' | 50' 50' | 25' 25' | 1.50 3.05 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | NA |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Scissor |

| Colors | 2 |

| Wall Thickness | .0625 - .125 |

| Specific Gravity | 2.6 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 1 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Maximum Continuous (MIL-I-23053) | 1,200°F/649°C |

| Melt (ASTM D-2117) | 2,048°F/1,120°C |

| Other Information | |

| UL/CSA | Yes |

| Halogen Free | Yes |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.