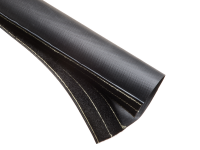

Techflex® Flexo® Heavy Wall Braided Cable Sleeving

Expands Up to 150% Over Nominal Size - Available in: 3/8" - 4" Dia

0.0 / 5

Flexo Heavy Wall Braided Sleeving Features

- Highly Abrasion & UV Resistant

- Resists Gasoline, Solvents, Salt Water & Chemicals

- Braided From 15 mil PET Monofilament

- UV Resistant

- Available Up to 4" in Diameter

- Operating Temperature Range -103°F to 257°F (-75°C to 125°C)

- Braided Design Does Not Retain Moisture

- Melt Temperature 446°F (230°C)

- Tested and approved for use under FAR 23/25, FMVSS 302, UL, and CSA material standards

- Inside Diameters Are Measured as Round Not Flat

Require Splice Free? Please Call 1-877-284-7760

Heavy Wall expandable sleeving is braided from 15 mil polyethylene terephthalate (PET) monofilament yarn that is 50% thicker than standard PET. This additional thickness provides more protection, durability, and enhanced abrasion resistance. This cable sleeving is tested and approved for use under FAR 23/25, FMVSS 302, UL, and CSA material standards. Additionally, it is in compliance with RoHS, the European directive on the Restriction of Hazardous Substances. Flexo Heavy wall braided sleeving is commonly used in industrial and outdoor applications. It is also highly used in marine applications because of its durability; which makes it perfect for protecting hoses and cables from constant contact with rough surfaces. Flexo heavy wall cable sleeving is also ideal for covering chains and protecting trailer hitch harnesses scuffing. To ensure professional, long-lasting installations, a hot knife or similar tool should be used to cut and seal the ends of the sleeving. When your application calls for more protection than our 10 mil products provide, our 15 mil Heavy Wall is the ideal solution. Heavy Wall braided sleeving is commonly used in industrial and marine applications where extreme abrasion protection is critical. The durability of the flexo Heavy Wall makes it ideal for protecting hoses and cables that have to withstand constant contact with rough and abrasive surfaces.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expans. Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| 1/8" 3/8" 5/8" 1" 1 1/2" 2" 3" 4" | HWN0.13BK HWN0.38 HWN0.63 HWN1.00 HWN1.50 HWN2.00 HWN3.00 HWN4.00 | 1/16" 3/16" 5/16" 1/2" 3/4" 1 1/2" 2" 2 1/2" | 3/16" 3/4" 7/8" 1 1/2" 2" 3" 4" 5 1/2" | 500' 500' 250' 250' 250' 200' 100' 100' | 125' 100' 75' 50' 50' 50' 50' 50' | BK 3 3 3 3 3 3 3 | 0.27 0.82 1.10 1.60 2.50 3.40 4.20 4.20 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .015 |

| Flammability Rating | UL94 |

| Recommended Cutting | Hot Knife |

| Colors | 3 |

| Wall Thickness | .038 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 10 |

| Abrasion Resistance | High |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| SVHC | None |

| UL/CSA | Yes |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Heavy Wall expandable sleeving is braided from 15 mil polyethylene terephthalate (PET) monofilament yarn that is 50% thicker than standard PET. This additional thickness provides more protection, durability, and enhanced abrasion resistance. This cable sleeving is tested and approved for use under FAR 23/25, FMVSS 302, UL, and CSA material standards. Additionally, it is in compliance with RoHS, the European directive on the Restriction of Hazardous Substances. Flexo Heavy wall braided sleeving is commonly used in industrial and outdoor applications. It is also highly used in marine applications because of its durability; which makes it perfect for protecting hoses and cables from constant contact with rough surfaces. Flexo heavy wall cable sleeving is also ideal for covering chains and protecting trailer hitch harnesses scuffing. To ensure professional, long-lasting installations, a hot knife or similar tool should be used to cut and seal the ends of the sleeving. When your application calls for more protection than our 10 mil products provide, our 15 mil Heavy Wall is the ideal solution. Heavy Wall braided sleeving is commonly used in industrial and marine applications where extreme abrasion protection is critical. The durability of the flexo Heavy Wall makes it ideal for protecting hoses and cables that have to withstand constant contact with rough and abrasive surfaces.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expans. Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| 1/8" 3/8" 5/8" 1" 1 1/2" 2" 3" 4" | HWN0.13BK HWN0.38 HWN0.63 HWN1.00 HWN1.50 HWN2.00 HWN3.00 HWN4.00 | 1/16" 3/16" 5/16" 1/2" 3/4" 1 1/2" 2" 2 1/2" | 3/16" 3/4" 7/8" 1 1/2" 2" 3" 4" 5 1/2" | 500' 500' 250' 250' 250' 200' 100' 100' | 125' 100' 75' 50' 50' 50' 50' 50' | BK 3 3 3 3 3 3 3 | 0.27 0.82 1.10 1.60 2.50 3.40 4.20 4.20 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .015 |

| Flammability Rating | UL94 |

| Recommended Cutting | Hot Knife |

| Colors | 3 |

| Wall Thickness | .038 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 10 |

| Abrasion Resistance | High |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| SVHC | None |

| UL/CSA | Yes |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.