Techflex® F6® Wrap Around Braided Cable Sleeving

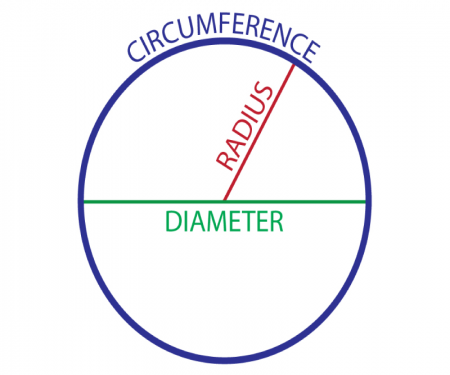

Easy To Install Side Entry - 5 Color Options - 1/8" - 2" Diameters

0.0 / 5

Techflex® F6® Wrap Around Sleeving Features

- Wrap Around Self Closing Design

- Economical & Easy to Install

- Cut & Abrasion Resistant

- 25% Edge Overlap

- Halogen Free

- Available in 5 Colors

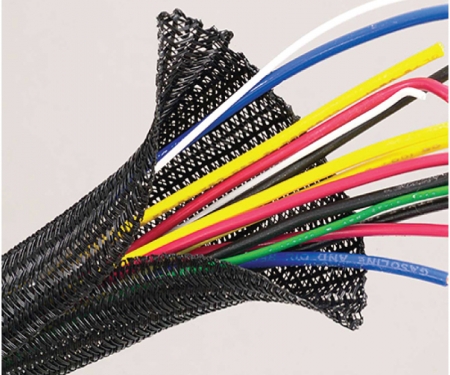

- Inside Diameters Are Measured as Round Not Flat

Flexo F6 wrap-around braided sleeving’s unique split, semi-rigid braided construction makes it the ideal solution for situations where ease of installation is of primary importance. The lateral split allows the tube to open up to accommodate a wide variety of bundling requirements, and the semi-rigid braid configuration simply closes around the entire installation without the need for any additional fasteners (velcro, tape, etc.). The 10 mil PET braid is lightweight, quiet, and flexible. The 25% edge overlap (at nominal diameter) allows coverage around inline plugs, connectors, and splices. F6 will bend to a tight radius without distorting or splitting open and, unlike full rigid tubing, will not impair or affect the flexibility of harnesses. While the majority of Order Ship Splice-Free There are instances where lengths may be spliced to meet length requirements, If you absolutely Require Splice Free? Please Call 1877-284-7760 to Confirm.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Bulk | Box A | Box B | |||||

| 1/8" 1/4" 3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | F6N0.13 F6N0.25 F6N0.38 F6N0.50 F6N0.75 F6N1.00 F6N1.25 F6N1.50 F6N2.00 | .024" .025" .025" .025" .025" .038" .038" .038" .038" | 8,000' 3,000' 1,500' 1,200' 500' 400' 250' 250' 200' | 400' 200' 150' 150' 100' 100' 75' 75' 50' | 100' 100' 75' 75' 50' 50' 25' 25' 25' | 4 4 4 4 4 4 4 4 4 | 0.47 0.60 1.20 1.40 1.60 2.00 2.40 2.70 3.60 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .008 - 015 |

| Flammability Rating | UL-94 |

| Recommended Cutting | Hot Knife |

| Colors | 4 |

| Wall Thickness | .024 - .038 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 6 - 10 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| SVHC | None |

| UL/CSA | Yes |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Flexo F6 wrap-around braided sleeving’s unique split, semi-rigid braided construction makes it the ideal solution for situations where ease of installation is of primary importance. The lateral split allows the tube to open up to accommodate a wide variety of bundling requirements, and the semi-rigid braid configuration simply closes around the entire installation without the need for any additional fasteners (velcro, tape, etc.). The 10 mil PET braid is lightweight, quiet, and flexible. The 25% edge overlap (at nominal diameter) allows coverage around inline plugs, connectors, and splices. F6 will bend to a tight radius without distorting or splitting open and, unlike full rigid tubing, will not impair or affect the flexibility of harnesses. While the majority of Order Ship Splice-Free There are instances where lengths may be spliced to meet length requirements, If you absolutely Require Splice Free? Please Call 1877-284-7760 to Confirm.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Bulk | Box A | Box B | |||||

| 1/8" 1/4" 3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | F6N0.13 F6N0.25 F6N0.38 F6N0.50 F6N0.75 F6N1.00 F6N1.25 F6N1.50 F6N2.00 | .024" .025" .025" .025" .025" .038" .038" .038" .038" | 8,000' 3,000' 1,500' 1,200' 500' 400' 250' 250' 200' | 400' 200' 150' 150' 100' 100' 75' 75' 50' | 100' 100' 75' 75' 50' 50' 25' 25' 25' | 4 4 4 4 4 4 4 4 4 | 0.47 0.60 1.20 1.40 1.60 2.00 2.40 2.70 3.60 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .008 - 015 |

| Flammability Rating | UL-94 |

| Recommended Cutting | Hot Knife |

| Colors | 4 |

| Wall Thickness | .024 - .038 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 6 - 10 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 2 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | Yes |

| RoHS | Yes |

| SVHC | None |

| UL/CSA | Yes |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.