Techflex® F6® Heavy Duty Wrap Around Braided Cable Sleeving

Available In 3/8" - 1-3/8" Dia - Side Entry Sleeving

0.0 / 5

F6 Heavy Duty Sleeving Features

- Quick & Easy Install Without Having to Disconnect

- Self Closing Wrap Around Design

- 51% Overlap

- Able To Be Cut With Scissors

- Extremely High Abrasion Resistance

- RoHs Compliant

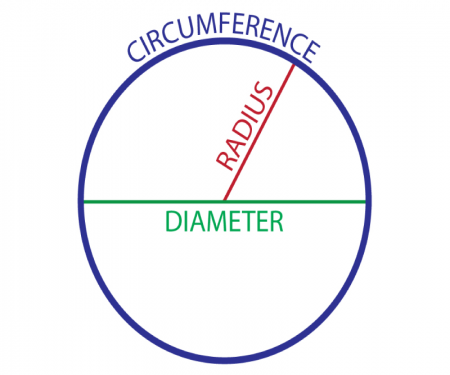

- Inside Diameters Are Measured as Round Not Flat

- Material: Polyethylene Terephthalate

- Color: Black

Require Splice Free? Please Call 1-877-284-7760

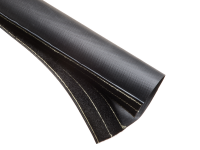

F6 Heavy duty braided sleeving is a unique composite wrap-around chafe guard made from resistant synthetic polymers. F6 Heavy duty sleeving is reimagined from the ground up to protect hoses and cables from chafing and abrasion. The easy wrap installation technology is a first for the hydraulic and fluid transfer industry. By combining the extreme cut and abrasion defense of a traditional woven nylon protection sleeve and the self-wrapping properties of the best-selling F6 line of products we have created a new standard for fast in field hose and wire protection. F6 Heavy duty sleeving eliminates the need to disconnect fittings, connectors and hoses in order to properly protect your systems from damage.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Standard Spool Put-Ups | Available Colors | Lbs/ 100' | ||

| Bulk Spool | Box A | Box B | |||||

| 3/8" 1/2" 5/8" 3/4" 1" 1 3/8" | F6H0.38BK F6H0.50BK F6H0.63BK F6H0.75BK F6H1.00BK F6H1.38BK | .06" .06" .06" .06" .06" .06" | 1200' 800' 500' 500' 400' 250' | 150' 100' 100' 100' 75' 75' | 75' 50' 50' 50' 25' 25' | BK BK BK BK BK BK | 3.2 3.9 4.7 5.0 6.2 7.5 |

| Physical Properties | |

| Recommended Cutting | Scissors |

| Colors | 1 |

| Wall Thickness | .06 |

| Abrasion Resistance | Extremely High |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .2.7 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 1.10 |

| CVCM | .01 |

| WVR | .69 |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 22 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | ||||

| Aromatic Solvents | 2 | |||

| Alipahtic Solvents | 1 | |||

| Chlorinated Solvents | 3 | |||

| Weak Bases | 1 | |||

| Strong Bases | 2 | |||

| Salt Water (O-S-1926) | 1 | |||

| Hydraulic Fluid (MIL-H-5606) | 1 | |||

| Lubricating Oil (MIL-L-7808) | 1 | |||

| De-Icing Fluid (MIL-A-8243) | 1 | |||

| Strong Acids | 3 | |||

| Strong Oxidants | 2 | |||

| Esters/Ketones | 1 | |||

| UV Light | 1 | |||

| Petroleum | 1 | |||

| Fungus (ASTM G-21) | 1 | |||

| Salts | 1 | |||

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | ||||

| Halogen Free | Yes | |||

| RoHS | Yes | |||

| SVHC | None | |||

| UL/CSA | No | |||

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

F6 Heavy duty braided sleeving is a unique composite wrap-around chafe guard made from resistant synthetic polymers. F6 Heavy duty sleeving is reimagined from the ground up to protect hoses and cables from chafing and abrasion. The easy wrap installation technology is a first for the hydraulic and fluid transfer industry. By combining the extreme cut and abrasion defense of a traditional woven nylon protection sleeve and the self-wrapping properties of the best-selling F6 line of products we have created a new standard for fast in field hose and wire protection. F6 Heavy duty sleeving eliminates the need to disconnect fittings, connectors and hoses in order to properly protect your systems from damage.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Standard Spool Put-Ups | Available Colors | Lbs/ 100' | ||

| Bulk Spool | Box A | Box B | |||||

| 3/8" 1/2" 5/8" 3/4" 1" 1 3/8" | F6H0.38BK F6H0.50BK F6H0.63BK F6H0.75BK F6H1.00BK F6H1.38BK | .06" .06" .06" .06" .06" .06" | 1200' 800' 500' 500' 400' 250' | 150' 100' 100' 100' 75' 75' | 75' 50' 50' 50' 25' 25' | BK BK BK BK BK BK | 3.2 3.9 4.7 5.0 6.2 7.5 |

| Physical Properties | |

| Recommended Cutting | Scissors |

| Colors | 1 |

| Wall Thickness | .06 |

| Abrasion Resistance | Extremely High |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .2.7 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | 1.10 |

| CVCM | .01 |

| WVR | .69 |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | High |

| Oxygen Index (ASTM D-2863) | 22 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | ||||

| Aromatic Solvents | 2 | |||

| Alipahtic Solvents | 1 | |||

| Chlorinated Solvents | 3 | |||

| Weak Bases | 1 | |||

| Strong Bases | 2 | |||

| Salt Water (O-S-1926) | 1 | |||

| Hydraulic Fluid (MIL-H-5606) | 1 | |||

| Lubricating Oil (MIL-L-7808) | 1 | |||

| De-Icing Fluid (MIL-A-8243) | 1 | |||

| Strong Acids | 3 | |||

| Strong Oxidants | 2 | |||

| Esters/Ketones | 1 | |||

| UV Light | 1 | |||

| Petroleum | 1 | |||

| Fungus (ASTM G-21) | 1 | |||

| Salts | 1 | |||

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | ||||

| Halogen Free | Yes | |||

| RoHS | Yes | |||

| SVHC | None | |||

| UL/CSA | No | |||

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.