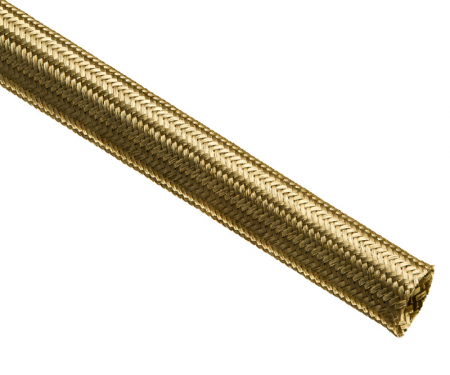

Techflex® Flexo® Brass Braided Cable Sleeving

Expandable - Anti-Microbial & Germicidal - (1/8" to 1/2" Sizes)

0.0 / 5

Brass Braided Sleeving Features

- Material: M88 Bare Brass

- Natural Antimicrobial / Germacidal Properties

- Looks & Functionailty

- Non-Flammable

- Ideal for Custom Hoses & Brake Lines

- Long Lasting

- RoHS Compliant

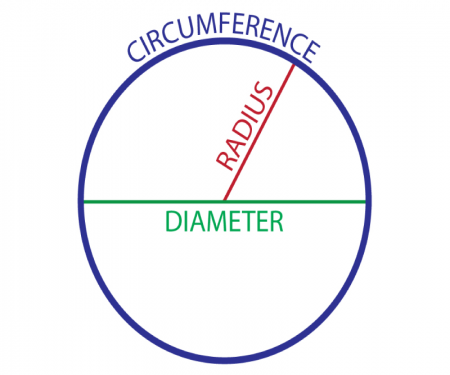

- Inside Diameters Are Measured as Round Not Flat

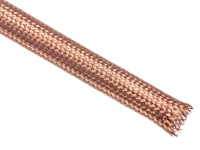

Brass Braided Sleeving can be a useful and beautiful part of your next project. The decorative features of brass are obvious but many people don’t know that brass is actually an alloy of copper and zinc. Brass braided sleeving is designed for both looks and functionality and can be adapted to create custom hoses and brake lines. Designers and engineers may also use brass braided sleeving for its natural antimicrobial and germicidal properties. Contact with our Brass Braided sleeving can kill harmful microorganisms within minutes. Brass Braid sleeving has been used in steampunk creations of all kinds to bring the hoses of the industrial revolution back to life today.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nom. Size | Product Part # | Wall Thickness | Expansion Range | Standard Spool Put-Ups | Color | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | |||||

| 1/8" 1/4" 3/8" 1/2" | MBB0.13BRS MBB0.25BRS MBB0.38BRS MBB0.50BRS | .015" .027" .015" .020" | 1/8" 1/4" 3/8" 1/2" | 1/4" 3/8" 3/4" 1" | 250' 100' 100' 100' | 25' 25' 25' 25' | BRS BRS BRS BRS | 0.9 3.0 3.0 4.2 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .005 |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Shears |

| Colors | 1 |

| Wall Thickness | .015 - .027 |

| Abrasion Resistance | Low |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | NA |

| CVCM | NA |

| WVR | NA |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | NA |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 5 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 2 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | NA |

| Maximum Continuous (MIL-I-23053) | NA |

| Melt (ASTM D-2117) | 1700°F/927°C |

| Other Information | |

| RoHS | Yes |

| UL/CSA | No |

| Halogen Free | Yes |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Brass Braided Sleeving can be a useful and beautiful part of your next project. The decorative features of brass are obvious but many people don’t know that brass is actually an alloy of copper and zinc. Brass braided sleeving is designed for both looks and functionality and can be adapted to create custom hoses and brake lines. Designers and engineers may also use brass braided sleeving for its natural antimicrobial and germicidal properties. Contact with our Brass Braided sleeving can kill harmful microorganisms within minutes. Brass Braid sleeving has been used in steampunk creations of all kinds to bring the hoses of the industrial revolution back to life today.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nom. Size | Product Part # | Wall Thickness | Expansion Range | Standard Spool Put-Ups | Color | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | |||||

| 1/8" 1/4" 3/8" 1/2" | MBB0.13BRS MBB0.25BRS MBB0.38BRS MBB0.50BRS | .015" .027" .015" .020" | 1/8" 1/4" 3/8" 1/2" | 1/4" 3/8" 3/4" 1" | 250' 100' 100' 100' | 25' 25' 25' 25' | BRS BRS BRS BRS | 0.9 3.0 3.0 4.2 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .005 |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Shears |

| Colors | 1 |

| Wall Thickness | .015 - .027 |

| Abrasion Resistance | Low |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | NA |

| CVCM | NA |

| WVR | NA |

| Smoke D-Max (ASTM E-662) | NA |

| Outgassing | NA |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 2 |

| Weak Bases | 1 |

| Strong Bases | 5 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-L-7808) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 5 |

| Strong Oxidants | 5 |

| Esters/Ketones | 1 |

| UV Light | 2 |

| Petroleum | 2 |

| Fungus (ASTM G-21) | 2 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | NA |

| Maximum Continuous (MIL-I-23053) | NA |

| Melt (ASTM D-2117) | 1700°F/927°C |

| Other Information | |

| RoHS | Yes |

| UL/CSA | No |

| Halogen Free | Yes |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.